Screen printing with water-based ink on waterproof fabric may seem like a daunting task, but with the right equipment and techniques, it can be done with great results. Unlike traditional screen printing methods that use plastisol ink, which is oil-based and requires heat to cure, water-based ink is composed of pigments suspended in a water-based solution, making it an eco-friendly and sustainable option. In this article, we will provide a step-by-step guide on how to screen print with water-based ink on waterproof fabric.

Materials Required:

- Waterproof Fabric

- Water-Based Ink

- Screen Printing Mesh

- Emulsion

- Screen Printing Frame

- Squeegee

- Exposure Unit/Light Source

- Scoop Coater

- Dehazer or Degreaser

- Water Hose

- Dryer or Heat Gun

Step-by-Step Guide:

1. Choose the right ink: Before starting the printing process, make sure that you have the right water-based ink suited for your fabric. Some inks work well on cotton and other natural fibers, while others are better suited for synthetic materials.

2. Prepare your artwork: Create your artwork using a computer program or by hand drawing onto a transparent film. The final design should be printed on a transparency that is slightly larger than your screen size.

3. Coat your screen with emulsion: The emulsion is a light-sensitive solution that will be used to transfer your design onto the screen. Using a scoop-coater, apply a light layer of emulsion onto the screen on both sides. Leave the screen to dry in a dark room.

4. Expose your screen: Once the emulsion is dry, it's time to expose your screen. Place your transparency on top of the emulsion-coated screen and secure it in place. Turn on your exposure unit or light source and expose the screen according to the manufacturer's instructions. Remove the transparency and wash the screen with water to reveal the design where the emulsion was not exposed.

5. Pre-treat your fabric: It is essential to pretreat the fabric to make it more receptive to the ink. This can be done by applying a dehazer or degreaser to the fabric and then washing it with water to remove any residues.

6. Set up your screen: Place the screen onto the fabric, making sure that it is properly aligned with the printing area.

7. Apply the ink: Using a squeegee, apply the ink to the screen while keeping it in place. Use a smooth and even motion to ensure that the ink is spread evenly across the screen. Apply enough pressure while pulling the squeegee to deposit the ink onto the fabric.

8. Repeat the process: If you need to print more than one color or layer, repeat steps 6 and 7 for each color.We recommend you add 5% color pigment by the weight of ink base.

9. Dry the fabric: Once the printing is complete, allow the fabric to dry naturally or use a dryer or heat gun to speed up the process.The WB ink can be self-drying.They will be cured thoroughly within 24hours.If you need fast dry,Please bake the every print at low temperature60-80℃,about 2hours.

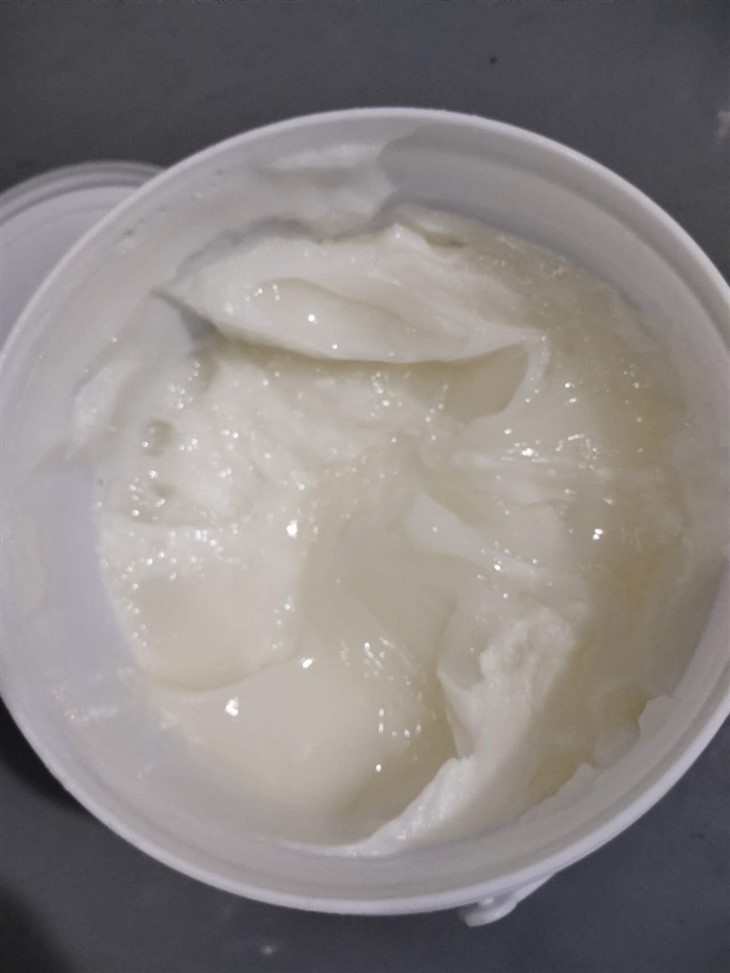

Water base ink picture:

Conclusion:

Screen printing with water-based ink on waterproof fabric is a great way to create eco-friendly and sustainable designs. By following the steps outlined in this guide, you can produce high-quality prints that are durable and long-lasting. With practice and experimentation, you can refine your technique and achieve even more striking results in your printing projects.

Hot Tags: water base ink for screen printing, suppliers, factory, custom, wholesale, buy, bulk, low price, in stock, free sample, made in China, Wholesale Glossy Silicone, Buy Screen Printing Textile Silicone, Bulk How To Print Glossy Ink, digital heat transfers, uniform printing, uv ink t shirt